Torque Converter

The torque converter connects and transfers power from the engine’s crankshaft to the transmission input shaft. It can act  as a clutch to stop this power flow when the vehicle stops. The converter can also multiply torque to improve vehicle performance.

as a clutch to stop this power flow when the vehicle stops. The converter can also multiply torque to improve vehicle performance.

AvCarb Material Solutions is a seasoned Tier 1 supplier to leading automotive OEMs. We have been the sole source supplier of woven carbon friction materials for more than 15 years with a strong track record for quality and on-time delivery.

With an extraordinarily stable coefficient of friction, AvCarb’s woven carbon friction material lasts well over 200,000 miles while maintaining its performance. Unique attributes include built in flow channels, ability to conform to opposing surface, excellent heat dissipation, consistent frictional characteristics and excellent durability.

The material solved a very difficult problem the powertrain engineers faced with NVH (noise, vibration and harshness) within the driveline. AvCarb’s friction material isolates driveline NVH to provide drivers the luxurious feel and quiet ride while giving the OEM a sense of security with extremely low warranty claims. At the same time, fuel economy improved when compared with earlier transmissions. AvCarb friction materials are in high volume production today. Click here to view our datasheet.

This innovation was the result of intensive collaboration between AvCarb’s engineering staff and the OEM’s powertrain engineering team. Our materials expertise combined with powertrain engineering’s understanding of system requirements delivered a ‘game changing’ technology. This co-engineering process is the model that consistently delivers innovative solutions.

Source :http://www.avcarb.com/applications/frictional-applications/torque-converter-auto/

Fishing

AvCarb engineers worked directly with leading fishing reel manufacturers to develop a solution that improved the stopping power and smoothness of fishing reel drags. Wet or dry, the material also maintains stable friction and dissipates heats throughout long fights.

AvCarb engineers worked directly with leading fishing reel manufacturers to develop a solution that improved the stopping power and smoothness of fishing reel drags. Wet or dry, the material also maintains stable friction and dissipates heats throughout long fights.

The AvCarb material provides a stable dynamic and static coefficient of friction, providing smooth line payout during fish striking, preventing line breaks. Many high end competition fishing reels as well as mainstream hobbyist’s reels now use AvCarb’s family of fishing drag materials to pull in their catch.

Collaboration between AvCarb and fishing reel manufacturers resulted in a powerful friction material solution that is now used broadly among reel makers around the world.

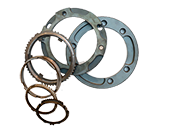

Cone Synchronizers

The friction energy created by the action of shifting gears in manual transmissions (MT), automated manual transmissions (AMT) or dual-clutch transmissions (DCT) requires a durable friction surface. AvCarb woven carbon friction materials are designed to provide exceptional durability and performance for these applications.

The friction energy created by the action of shifting gears in manual transmissions (MT), automated manual transmissions (AMT) or dual-clutch transmissions (DCT) requires a durable friction surface. AvCarb woven carbon friction materials are designed to provide exceptional durability and performance for these applications.

A cone synchronizer acts as a clutch, allowing the two gears to spin at the same speed just prior to the gears meshing. This allows for smooth transitions between gears during vehicle operation. Passenger cars, heavy duty trucks, even Lamborghinis are adopting this rapidly improving technology for their next generation vehicle designs.

As transmission technology advances, so do the demands on the cone synchronizers. Many OEMs are transitioning from traditional linings such as sintered metal to AvCarb’s woven carbon friction material due to its unique ability to dissipate heat, provide cold shift performance, and remain highly durable throughout its life, even in the extreme duty cycles of new transmission designs.

Source: http://www.avcarb.com/applications/frictional-applications/cone-synchronizers/

Rear Differentials

In rear wheel drive vehicles ranging from passenger cars to heavy duty trucks, transferring torque from the drive shaft to the rear wheels creates both mechanical and frictional challenges. The rear differential divides torque between the two tires equally at all times while allowing the

In rear wheel drive vehicles ranging from passenger cars to heavy duty trucks, transferring torque from the drive shaft to the rear wheels creates both mechanical and frictional challenges. The rear differential divides torque between the two tires equally at all times while allowing the

tires to rotate at different speeds.

AvCarb woven carbon friction material provides OEMs a valuable tool in managing the ‘slip’ between the rear wheels. The durability, low wear, and smooth frictional characteristics of AvCarb materials ensure stable performance over the life of the vehicle, even in difficult duty cycles such as those of heavy duty mining equipment.

Source :http://www.avcarb.com/applications/frictional-applications/rear-differentials/